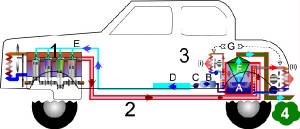

This is the comparison of the “Fuel Hog” in the drive way,

with “The Planet Broken Car.”

(All graphics are shown enlarged for clarity only, actual

components will be relatively smaller and fit easily under the hood of the average vehical)

The Fuel Hog

First, it would do well to understand some basics of “that” car in your driveway.

It possibly has the fundamental features and characteristics of the illustration here titled

“The Fuel Hog”.

Which hasn’t changed much since Henry Ford broke out that wall to release his first

“Horseless Carriage” on the world.

In the illustration, it has its motor up front at (1), with a simple cooling system, and showing

the exhaust system. The drive train has been left out for clarity for this discussion,

which will focus on efficiency and pollution in regard to the internal combustion engine (ICE) in its primary function.

Conventionally the (ICE) is in a vehicle to burn fuel and produce power; however in doing this

it produces air pollution as well. Something not always realized though, is that it releases massive amounts of “heat

pollution” from the fuel as it is burned also. Not only in the engine but as the hot exhaust is carried down the exhaust

system (2) it enters (3a), a catalytic converter, here the remaining unburned fuel gets “catalytically burned”, the

sound reduced by the muffler (3b) and everything dumped into our air at “X” (4).

Inversely;

Direct Water injection

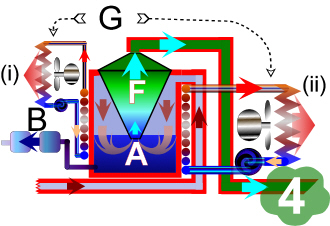

It may look like the “Fuel Hog” but that’s only “skin deep”, under that skin

it still has the same motor, but with some additional piping and apparatus, and the exhaust system also seems a little different.

On closer look it will be found that the motor has changed in characteristic behavior in fact, all by way of some reasonably

minor adaptation.

It now expands and improves on the internal combustion engine cycle, by incorporating a closed circuit steam

"sub cycle” into the conventional engines' combustion sequence.

At the motor (1), immediately after the explosion in the combustion chamber, a metered amount of water is injected,

which is calibrated to absorb most of the heat released from combustion of the air/fuel mixture in the cylinder, but

will still evaporate the water to steam completely. In addition to producing more power, the steam also

loads the exhaust gases with humidity. When the humidity is reclaimed, it brings with it the "Acid Rain

type of GHGs" because it now has effectively scrubed the exhaust gases by the same principle of rain condensing

from our sky (condensation on cooling)

In practical application; to increase fuel efficiency to the full 25% in

using this system, it would require about 10/1 water to fuel. Yes, that is ten gallons of water for every gallon

of fuel, and carrying so much water wouldn't allow for portability, so reclaiming/restoring the water from the exhaust

as condensate is the only practical choice.

Condensate reclaim;

'the GHG Scrubber'

This is where the 'Water soluable GHG's are removed;

The water is exported from the motor as steam

with the other products of combustion, down the exhaust piping (2), as exhaust usually would except that it gets diverted

up and into a canister, emptying into an expanding volume adjacent to space (F) slowing the speed of the gases down. This

“Condenser” (A) has a cooling coil wrapped around it, starting with the cool glycol/ water cooling solution entering

at the lowest coil (the small blue circle) and encircling it in a spiral up on the outside of the container, (to the small

dark red circle above), This coil is also interconnected with heat ejection components (G) at points (i) and (ii).

The steam is condensed by extracting the heat through the

cooling coil, and ejecting it to the atmosphere, reconstituting the steam back to water, however, along with the water,

just like when it rains in nature, the gases that condense with water there also condense here, causing the same thing, “Acid

Rain”. The “Filter Bank” (B) removes these pollutants, and neutralizes and cleans the water, pump (C) then

delivers it to the water reservoir (D), and up the piping, to be re-introduced by the metering apparatus at (E) back

into the (ICE) combustion cycle. This completes the “Acid Rain loop” within the “Steam Explosion/Pollution

Extraction sub-cycle”.

The exhaust that didn’t condense with the steam, bubbles

through the water (at a level just above) (A), before it enters (F).

As it enters, (F) it comes into another space

of expanding volume, (just as it did on entering into the condenser) slowing its speed down again. The hot exhaust, fresh

from the motor on the other side of the conical wall, is transferring heat to this space as well as to the cooling system,

and as the heat in (F) increases and the humidity drops, the hotter drier gases rise and are the first to be pushed up and

out of this area and then down and out of the exhaust terminal at (4).

The resulting combustion products have in this

way been subject to a highly concentrated form of “Acid Rain” within the confines of the system, prior to discharge

to our atmosphere. Hence the exhaust now no longer contains the chemicals that cause our precipitation to become acidic, and

can not present these chemicals since they were already captured and removed. So we no longer need to breathe them, and they

can’t result in any more “Acid Rain" either.

The (ICE) combustion cycle, re-characterized

in this way may also eliminate the need for *MMT that is used in Canadian fuels, as a replacement for tetra-ethyl lead, altogether,

if not that, then at least remove the toxic results of its combustion, *magnesium oxides. This along with arresting diesel

particulate will reduce much asthma and bronchial irritation, not to mention the stomata on the underside of leaves, that

diesel particulate also “plugs up” which is stifling our plant life.(*suspected of causing brain cell development

problems in children)

Since the steam reclamation starts immediately when the motor

starts, the cooling coil at the condenser gets hot very quickly, so the interior heat fan at (i) can start cab heat almost

immediately, all excess heat being discharged at (ii).

The reason it gets hot so quickly, is that the

system may be “dry” at the start, but immediately starts to extract heat and condensate from the exhaust. This

“dry” exhaust has a high temperature of 2,000ºF+, and has a very low relative humidity (rh) at that temperature,

(whereas the “saturated” exhaust is expected to reach the condenser at about 450ºF and 75%+ relative

humidity, the quantity of heat energy contained, remains close to the same).

As it’s cooled the (rh) rises to 100% and

the condenser starts filling by condensing and extracting the water vapor out of the exhaust products, as it fills to operating

level.

Or the system can start out filled, and then the injection/extraction cycle can start immediately to perform in

both procedures.

What is not easily deducted from this is that

the system would extract more water vapor from the exhaust gases than the water that was injected into the motor (one of the

results of hydrocarbon combustion is water vapor about 1/1). So the reservoir requires an overflow relief valve to “dump”

this clean ‘rain water’, also that the system must have and use all of the described components in proper operation

for its most efficient function.

With out reclaiming the condensate for instance, the cost

of replacing the (distilled) water would make it as unprofitable as not using the system in the first place.

Attraction more than promotion, will bring about this change,

and it may be considered ‘thinking outside of the box’, however, the most noticable reset parameter

is the long held presumption that, “pollution reduction is always costly”, while this actually pays back.

Addressing this through a sensible

method that is quite easy to understand, and having the common result of us knowing that we are genuinely helping to reduce

fuel consumption and pollution in a practical and meaningful way, offers hope and instills a confidence for the future.

Alternatively; the

case out there right now, us dumping (ICE) combustion pollutants into the atmosphere continuously, and then worrying about

the pollution, “acid rain” etc. and all of the effects, to the land, water, air and showing up in our food

chain.

The options are.....either,.. change, or keep

on, keeping on, as we were...

Ultimately; this should be seen only as a “Stop-gap”,

interim measure, to reduce the damage being done currently, by (ICEs’) to our earth by their fossil fuel combustion.

It is nearly imperative that we develop new, better energy sources, and that we conserve known hydrocarbon sources prudently

for the benefit of our future generations, this will buy us some valuable time to pursue both...

|